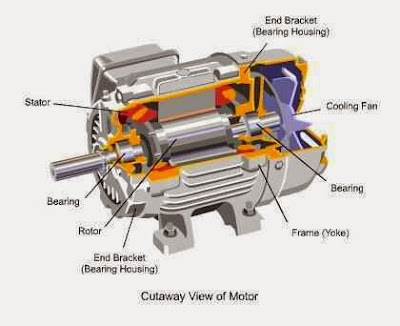

In this topic you learn the construction of motor step by step:

Rotor:

In an electric motor the moving part is the rotor which turns the shaft to deliver mechanical power. The rotor usually has conductors which carry currents that interact with the magnetic field of the stator to generate the forces that turn the shaft. However, some rotors carry permanent magnets, and the stator holds the conductors.

Stator:

The stationary part is the stator, usually has either windings or permanent magnets. The stator is the stationary part of the motors electromagnetic circuit. The stator core is made up of many thin metal sheets, called lamination's. Lamination are used to reduce energy losses that would result if a solid core were used.

Air Gap between rotor and stator:

Between the rotor and stator is the air gap. The air gap has important effects, and is generally as small as possible, large gap has a strong negative effect on the performance of an electric motor.

Windings:

Windings are wires that are rounded in coils, usually wrapped around a laminated soft iron magnetic core so as to form magnetic poles when energized with current. Electric machines has two basic magnet field pole configurations one is salient-pole machine and second is non salient-pole machine. In the salient-pole machine the pole's magnetic field is produced by a winding wound around the pole below the pole face. In the non salient-pole, or distributed field, or round-rotor, machine, the winding is distributed in pole face slots. A shaded-pole motor has a winding around part of the pole that delays the phase of the magnetic field for that pole.

Some motors have conductors which consist of thick metal, such as bars or sheets of metal, usually copper, although sometimes aluminum is used. These are usually powered by electromagnetic induction.

Commutator:

A commutator is a mechanism used to switch the input of most DC machines and certain AC machines consisting of slip ring segments insulated from each other and from the electric motor's shaft. The motor's armature current is supplied through the stationary brushes in contact with the revolving commutator, which causes required current reversal and applies power to the machine in an optimal manner as the rotor rotates from pole to pole.In absence of current, the motor would brake to a stop. In light of significant advances in the past few decades due to improved technologies in electronic controller, sensor less control, induction motor, and permanent magnet motor fields, electromechanically commutated motors are increasingly being displaced by externally commutated induction and permanent-magnet motors.

Conclusion: After this you can make simple small motor at home. Doing this makes you a practically good and intelligently strong in physics